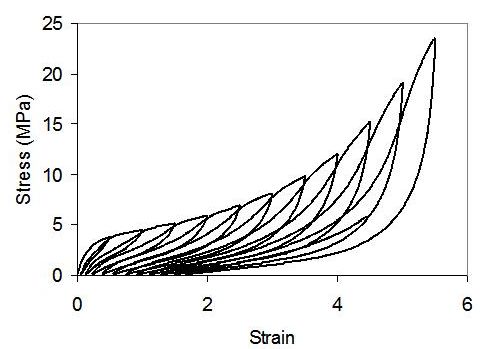

Elastomers exhibit a phenomenon known as the Mullins Effect when they are loaded, unloaded and reloaded. The way they behave depends on what has happened to them before. This makes the modelling of such materials particularly challenging, as any model must evolve with the deformation. We have been looking at how this effect manifests itself when elastomers are deformed multi-axially by using a biaxial machine especially adapted for this purpose, and series of carefully planned experiments.

Tensile deformation of a filled elastomer showing the Mullins effect

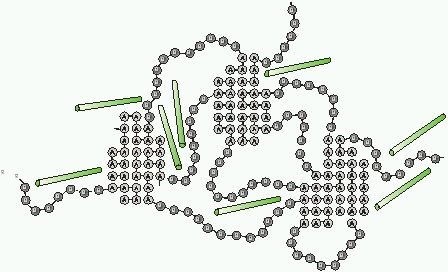

By filling the elastomers with special nanoparticles such as carbon nanotubes, other properties such as thermal and electrical conductivity can be made to change in well-defined ways with deformation. This area has interesting applications for the development of sensors and smart materials.

A thermoplastic elastomer filled with carbon nanorods

Continue to Elastomer Modelling, or return to Elastomers.

For a list of publications relating to elastomers go here.

Back to Research.